Underground utility construction is one of those project phases where everything looks fine until it is not. A missed conflict, a rushed sequence, or unclear scope can snowball into rework, delays, and change orders that impact the entire job.

Whether you are an owner, GC, or facility manager, understanding the basics of underground utility construction helps you ask better questions, compare bids more accurately, and keep the project moving when multiple trades overlap.

This guide breaks down what underground utility construction typically includes, how it connects to grading, paving, and structural work, and the most common pitfalls we see on real sites. We will also touch on why site utility installation needs tight coordination and how utility conflict investigation reduces risk before crews mobilize.

What underground utility construction includes

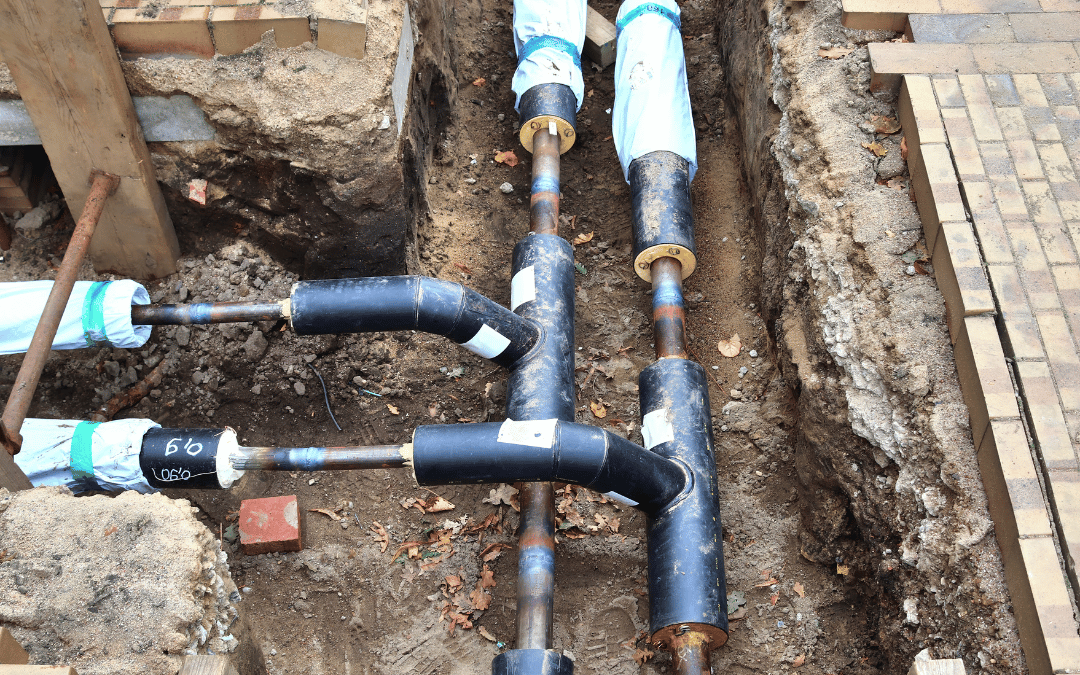

At a high level, underground utility construction covers the installation of buried infrastructure that serves a site or connects it to municipal systems. Scope varies by project, but commonly includes:

- Storm sewer systems and drainage structures

- Sanitary sewer mains and service connections

- Water mains, hydrants, and service lines

- Detention systems, infiltration systems, and related drainage components

- Manholes, catch basins, inlets, and associated structures

- Trenching, bedding, backfill, and compaction requirements

- Testing, inspections, and documentation tied to local requirements

The important part: underground utilities are not “just digging and dropping pipe.” The work must match elevations, slopes, and tolerances, and it has to work with the rest of the site design.

Why sequencing matters more than most people expect

Underground utilities touch nearly every major phase of sitework. If they are sequenced poorly, the project can end up doing the same work twice.

Here is why sequencing is so important:

- Utilities depend on grades and elevations. If grading is not aligned, pipe elevations can be wrong.

- Paving depends on subgrade and compaction. If trenches settle, asphalt fails.

- Foundations and structural work need clear access. Utility installation can block crane paths, staging, and footing excavation.

- Erosion control and drainage must work early. If stormwater is unmanaged, the site gets messy and productivity drops.

When underground utility construction is planned correctly, each step sets up the next. When it is rushed, it creates conflicts that cost time.

A simple sequencing overview that usually works

Every project is different, but a practical baseline sequence often looks like this:

1) Preconstruction utility conflict investigation

Before excavation begins, confirm existing conditions. This typically includes utility locating, record review, and coordination to identify likely conflicts.

This is where utility conflict investigation saves money. It reduces surprises like unknown lines, mismatched as-builts, or utility depths that do not match plans.

2) Clearing, access, and erosion control

Stable access and erosion control should be installed early. Without them, the site turns into mud, trucks track sediment, and inspections get stressful fast.

3) Rough grading and mass earthwork

Mass grading establishes the “big shapes” of the site and provides working room for trenching and structures. It also helps define drainage paths so stormwater is not fighting your operation.

4) Deep utilities and main runs

Install deeper utilities first where feasible. This reduces the risk of cutting through newly installed lines later.

5) Structures, connections, and tight tolerance work

Manholes, catch basins, and connections require accuracy and coordination. Small elevation mistakes can become big operational problems.

6) Fine grading, proofrolling, and paving prep

Once utilities are in and tested, you can move toward subgrade, final grading, and the layers that support paving or slabs.

This sequence is not rigid, but it is a strong starting point. The goal is to minimize rework and keep equipment moving efficiently.

Common pitfalls that cause delays and rework

Pitfall 1: Unclear scope boundaries between trades

This is one of the most common problems in site utility installation. The project assumes “someone else” is doing it.

Examples:

- Who installs and maintains erosion control around utility work?

- Who handles utility locates and potholing?

- Who provides trench backfill and compaction testing?

- Who restores disturbed areas temporarily between phases?

Fix: Document responsibilities early and make sure they match the bid language.

Pitfall 2: Relying only on records for existing utility locations

As-builts and utility maps are helpful, but they are not perfect. Depths are often missing or inaccurate, and field conditions change over time.

Fix: Treat utility locating and verification as a real work item, not a formality. Use potholing where it reduces risk.

Pitfall 3: Installing utilities before grades are truly understood

If grades shift after utilities are in, you can end up reworking structures, resetting elevations, or fighting drainage issues later.

Fix: Confirm benchmarks, control points, and grading intent before critical utility elevations are set.

Pitfall 4: Trench backfill and compaction getting rushed

Poor compaction shows up later as settlement, pavement failures, and callbacks.

Fix: Set expectations for compaction and testing frequency, and make sure the schedule supports doing it right.

Pitfall 5: Poor coordination with paving and structural schedules

Underground utility construction often overlaps with concrete, steel, or paving. If coordination is not tight, crews end up waiting or working around each other, and productivity suffers.

Fix: Align the look-ahead schedule across trades and define access routes, staging, and no-go zones.

Pitfall 6: Stormwater not managed during utility work

Trenches fill with water, soils get unstable, and progress slows. This is especially true in wet seasons.

Fix: Plan water management and dewatering needs early, including discharge approach where applicable.

What to look for in a strong underground utility plan

If you are reviewing a proposal or planning the work, these are good signs:

- Clear description of underground utility construction scope, not vague wording

- Defined sequencing and coordination plan with grading and paving

- Unit pricing or assumptions for common unknowns (rock, unsuitable soils, extra dewatering)

- A plan for utility conflict investigation and verification

- Specific compaction and testing approach

- Clear responsibilities for erosion control, maintenance, and restoration

You do not need a 40 page plan. You need a plan that is realistic and specific enough to execute.

Quick questions owners and GCs should ask

Use these questions in preconstruction or during bid review:

- What is your process for locating and verifying existing utilities?

- What are the biggest risks on this site and how will you mitigate them?

- How will you coordinate utility installation with grading and paving?

- What assumptions are you making about soils, water, and access?

- What is your compaction and testing plan for trench backfill?

- How do you handle conflicts discovered after work starts?

- Who owns erosion control maintenance during utility work?

The answers tell you who is organized, who is guessing, and who has been through the hard situations before.

The takeaway: underground utilities are where coordination wins or loses

Underground utility construction is not just a phase. It is a foundation for everything that comes next. When scope is clear, sequencing is planned, and utility conflicts are investigated early, projects move faster and with fewer surprises.

If you are planning a Michigan project and want help coordinating site utility installation, grading, and drainage work, Verdeterre can help you build a practical plan that reduces rework and keeps the schedule intact.